CLASSIC CAR MEETS FUTURE TECHNOLOGY: VW CADDY FITTED WITH 3D-PRINTED FRONT-END STRUCTURE

Individualize, integrate, innovate: 3i-PRINT partnership project highlights the potential of industrial 3D printing

Krailling, Germany, August 29, 2017 – Altair, APWORKS, csi entwicklungstechnik, EOS GmbH, GERG, and Heraeus have used the front-end structure of a classic VW Caddy to demonstrate the full potential of industrial 3D printing within the automotive industry. The structure is very light, stable, and, at the same time, features a high degree of functional integration. In this joint development project known as 3i-PRINT, the involved companies covered every development step of the process, from design, simulation, optimization and manufacturing to post production of the part. From conceptual design to final vehicle, the project was completed in only nine months.

Value of additive manufacturing for the automotive industry

Driving innovation, impacting decisive development processes, over the next few years, industrial 3D printing, also known as additive manufacturing (AM), will play an integral role in large-scale manufacturing. The technology is already being deployed in a wide range of industries. The constant evolution of production and design techniques using AM will make the technology even more cost-effective and efficient in the future. In other words, the use of industrial 3D printing will continue to grow – also in the automotive industry. In order to drive innovation and decisively form development processes, it is essential to explore all possibilities in the fields of design and additive manufacturing today.

The true value proposition of additive manufacturing in automotive engineering can be realized only with considerations extending far beyond structural mechanics and lightweight construction. This functional integration –implementing as many technical features as possible with as few components as possible with the resulting added value, is an additional key advantage that makes the use of 3D printing lucrative for the automotive industry. With the Caddy concept, the 3i-PRINT project aims to demonstrate future technological possibilities.

Organic design for load-bearing structures

In view of the growing trend towards electrification in the automotive sector, for example of drive train and actuators, heat management as well as the reduction of design space and overall weight were crucial points when designing the front-end section. Moreover, structural requirements relating to vehicle safety, performance, and comfort needed to be addressed.

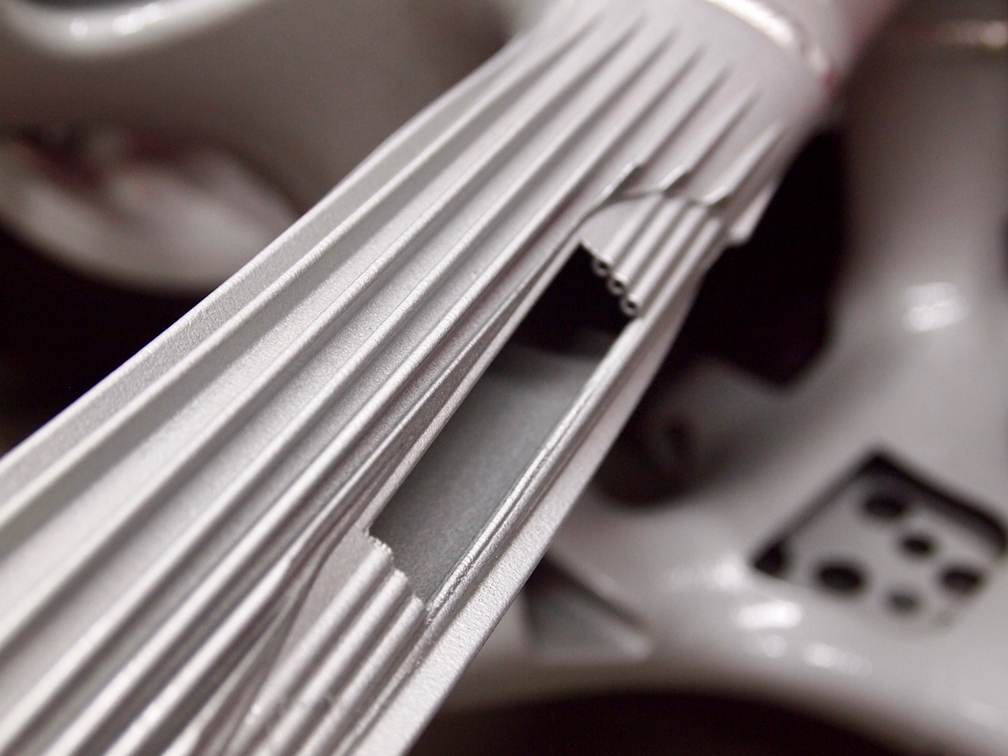

Accordingly, parts of the additively manufactured front are load-bearing structures that include details for both active and passive cooling – for example with a channeled airflow to cool batteries and brake systems. In addition, functions linked to heat management, passive safety, and fluids storage have been integrated in the organic, load-driven design of the front-end module. One example for the integration of additional functions into the structure is the fountain solution tank, which could be integrated into the front end structure when conducting the topology optimization.

Combined expertise along the process chain

With these goals in mind, the experts at csi entwicklungstechnik began designing, developing, and building the front end structure. The company develops high-quality modules for vehicle bodies, interiors, and exteriors for both manufacturers and suppliers in the automotive sector. GERG is a leading supplier of innovative solutions in the area of prototyping and small-scale series for the automotive and aerospace industries. In this project GERG was responsible for connecting the additively manufactures components and the creation of the final frame. With their focus on the development and broad application of simulation technology to synthesize and optimize designs and processes, Altair's software solutions were used to design, optimize, simulate, and develop the structure.

After the successful simulation and design of the concept, APWORKS took care of the final dimensioning of the components for 3D printing. APWORKS contributed its knowledge of print preparation and handled the actual additive manufacturing of the structural elements. As a subsidiary of Airbus, the company is very familiar with state-of-the-art manufacturing processes and enables various industries to implement best practice concepts from the aerospace sector. When printing the front end, APWORKS relied on a system developed by EOS, the leading technology supplier in the field of industrial 3D printing of metals and polymers. Metal powder specialist Heraeus supplied and qualified the high-strength aluminum alloy Scalmalloy®, developed by APWORKS, to manufacture the components. APWORKS provided support for the printing process by developing the ideal printing parameter sets for the EOS M 400 system. Thanks to the combined use of AM and this innovative material, the project successfully demonstrates the possibilities of functional integration that traditional manufacturing methods are unable to offer.

The 3i-PRINT project, a forum for innovative prototype concepts

Initiated by csi entwicklungstechnik, the 3i-PRINT project acts as an agile engineering platform for research and development enabling innovative prototype concepts. The idea is based on the use of new development tools and methods, including industrial 3D printing. The project's goal is to demonstrate and fully exploit the potential of state-of-the-art manufacturing methods. The 3i-PRINT project is an open platform for collaboration that quickly enables the implementation of new ideas.

Stefan Herrmann, responsible for light weight design within the body in white team at csi, said: "We are proud to present the Caddy with an exemplary new additively manufactured front end structure. The new structure and the contrast between old and new impressively demonstrates the potential that 3D printing and functional integration offer, particularly for the automotive industry." He continues: "I would also like to emphasize the agile, time-efficient route from the initial idea to the fully converted vehicle, which was completed within only nine months. Each of the participating companies is a leader in its field. The outstanding collaboration and combined expertise has made the 3i-PRINT project a resounding success."

Among other events, the Caddy can be viewed at the Converge 2017 in Essen and the formnext 2017 in Frankfurt.

For more information please visit: www.3i-print.com.

About Altair

Altair is focused on the development and broad application of simulation technology to synthesize and optimize designs, processes and decisions for improved business performance. Privately held with more than 2,600 employees, Altair is headquartered in Troy, Michigan, USA and operates 67 offices throughout 23 countries. Today, Altair serves more than 5,000 corporate clients across broad industry segments. To learn more, please visit www.altair.com.About AIRBUS APWORKS GmbH:

As a 100 % subsidiary of Airbus, AIRBUS APWORKS GmbH makes proven aerospace technologies accessible in many different industries. Focusing on metal 3D printing (additive manufacturing) the company covers the entire value chain, from optimized component and part design to the choice of suitable materials, from prototyping to qualified serial production. Customers in robotics, mechanical engineering, automotive, medical technology and aerospace benefit from functionally integrated and optimized parts with reduced weight and lead time. 3D printing also allows much more complex geometries than were previously possible. AIRBUS APWORKS GmbH has been located on the Ludwig Bölkow Campus in the south of Munich since 2013. http://www.apworks.de/en/

About csi entwicklungstechnik GmbH

csi entwicklungstechnik GmbH is a development partner of the automotive industry, employs around 600 people and has its headquarter in Neckarsulm, Germany. Further branches are located in Ingolstadt, Sindelfingen, Munich, Wolfsburg, Zwickau, Weissach and Winterberg (ALU-CAR). Major automotive manufacturers and numerous system suppliers rely on csi know-how during the development of complete modules for surfaces (strak), body-in-White, exterior, interior and electronics. Focused on the product development process of the automotive industry, csi entwicklungstechnik teams also support their customers with consulting services, initial and continuing education at csi academy, as well as project management. The aim is assuring constant transparency – overarching all development phases. www.csi-online.de

About EOS

EOS is the world’s leading technology supplier in the field of industrial 3D printing of metals and polymers. Formed in 1989, the independent company is pioneer and innovator for comprehensive solutions in additive manufacturing. Its product portfolio of EOS systems, materials, and process parameters gives customers crucial competitive advantages in terms of product quality and the long-term economic sustainability of their manufacturing processes. www.eos.info

About Modell- und Formenbau Blasius Gerg GmbH

Gerg manufactures components and assemblies as prototypes or in small series for the automotive and motorsport industries, as well as precision components for aerospace and medical technology. Thanks to our enormous in-house production depth our customers get complex high-end products from one single source: process engineering, machining, CFK lightweight structures, laser melting, lighting technology, coating, laser welding, assembly and final inspection. We materialize ideas. www.gerg.de/en/

About Heraeus

Heraeus, the technology group headquartered in Hanau, Germany, is a leading international family-owned company formed in 1851. With expertise, a focus on innovations, operational excellence and an entrepreneurial leadership, we strive to continuously improve the businesses of our customers around the world. We create high-quality solutions for our customers and strengthen their long-term competitiveness by combining material expertise with technological know-how. www.heraeus.com

Contact:

EOS GmbH Electro Optical Systems

Martin Grebner

Press Officer

Tel.: +49-89-893-362-264

martin.grebner@eos.info

Altair Europe /the Middle East/Africa

Evelyn Gebhardt

+49-6421-9684351

gebhardt@bluegecko-marketing.de

Altair Corporate/Americas/Asia Pacific

Biba A. Bedi

+1-757-224-0548 x 406

biba@altair.com